After a day or so of a break, I sat down again with some Internet search results, my headphones, the stereo jack, and its schematics. I just needed to clear my head. I am pretty sure I understand how it works now, and that I can solder only the 3 pins I need for the circuit schematic.

But I figured I may as well buy a handful of mono jacks in the same order as the switches I need. I’m sure the extra stereo jack will come in handy in another project!

And of course, with a cooler head (and different tool), I managed to get the snipped mono jack out of the case. I’m trying not to be miffed at myself for being so rash as to cut it off without thinking through the stereo jack problem. It’s just more experience, I suppose.

So! I’m waiting for that order plus a new solder fume extractor before I solder leads to the trimpot and mono jack.

I’m currently working on NT7S’s Code Practice Oscillator. I was intimidated for awhile even after buying all the parts for it, but I finally went for it yesterday and…

View post on imgur.com

I realized I got the wrong kind of switch; but hey! I got an LED lit and I can switch it on if I want to!

I attempted the rest of the circuit, despite a lot of problems, and because of those problems (and being a beginner), I can’t properly troubleshoot–despite trying for an hour with my multimeter. At the end of the day, I broke down the breadboard to just the LED.

Here are the problems I noted:

- The trimpot I got doesn’t fit in the breadboard easily, so I substituted with a 3.3k resistor. I am now thinking that this is the main problem (or at least the first to address). As I looked at trimpot schematics I realized that they have 3 separate pins, not 2 like a resistor.

- The wrong switch: I got a SPST-NO (momentary on) rather than an on-off like for a lightswitch. This, at least, is an easy fix with my wallet. For now, the switch is out, replaced by a wire.

- 3.5mm stereo jack for headphones: not so much a problem with the hardware, so much as a problem with the user/builder (me!). First, the schematic calls for a mono jack but I had to be extra and get stereo. Second, I have no fucking clue how to wire these 5 pins and every search engine result is about soldering/fixing the plug and not the jack! I couldn’t wrap my head around it. Please forgive me, but I cut the wires of the 3.5mm mono from my existing practice oscillator (MFJ-557) and attempted to jerryrig additional wire to connect to my breadboard, because I couldn’t figure out how to uninstall the actual headphone jack from the plastic enclosure. Of course, since nothing else is working, I have no idea if the jerryrigging worked or not. Perhaps I shouldn’t have snipped so soon.

I’m going to try getting that trimpot in there for my 2nd try. And if I can’t bend them in, I’ll solder leads to the trimpot pins. While I’m soldering, I may as well solder longer leads to the jack I commandeered, too…

Should I have started on an easier oscillator/schematic? Maybe! I did decide I’d like to build a stepped tone generator (aka the Atari Punk Console) at some point. So if my 2nd attempt fails, I will probably take a break and attempt the APC instead. Less components, hopefully less opportunity for failure, and less frustration for me. I don’t want to become so discouraged that I want to quit. But this project so far is showing me I am not as well-equipped or as knowledged as I thought I was. That’s okay. I’ve already had several private temper tantrums about it.

Hope all is as well as can be for you, reader.

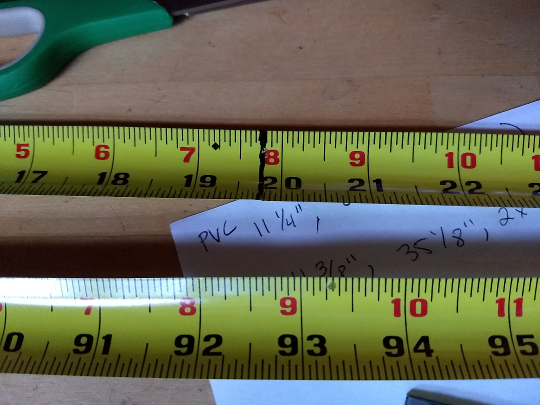

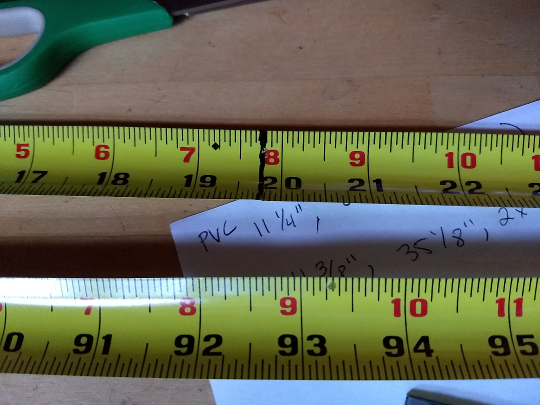

I guess I can start that single-lever paddle during this pandemic… since I finished the tape measure yagi today! It was a pleasant day weather-wise, and I loved being in the barn workshop looking out into the field whenever I needed a break.

Construction of the driven element

You only work as well as your weakest link… And that weakest link was my soldering iron.

I spent about 6 hours, minus a lunch break and a couple pee breaks. Most of the day was staging my “mise en place” for soldering–twisting wires, carefully placing things in place, then a few mins of soldering (mostly making mistakes), unplugging my soldering iron when it got too hot, then re-staging everything.

Oh boy, do I absolutely regret grabbing my cheap-o soldering iron! It’s not even the iron that’s giving me problems, it’s the cheap tips that it came with. They disintegrate when they get too hot. Good thing they included 5. Yup. I don’t even have a fume extractor yet so I’m sure I’ve breathed in a lot of fun metals.

After reading that most good soldering tips will last you years…I’ve been facepalming myself ever since discovering what was happening to my tips.

Oh, and I didn’t even mention that the soldering iron would get too hot about oh, every 3 minutes, and that’s at the iron’s lowest setting (200C), though who knows if that dial even works.

I can not wait to try the irons I left at the shop.

More …

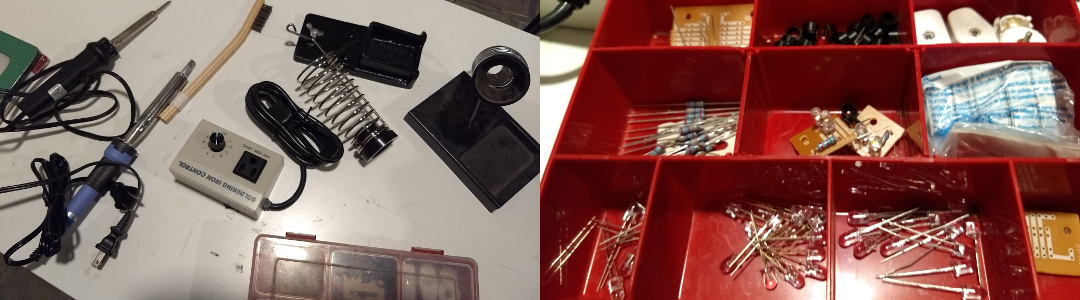

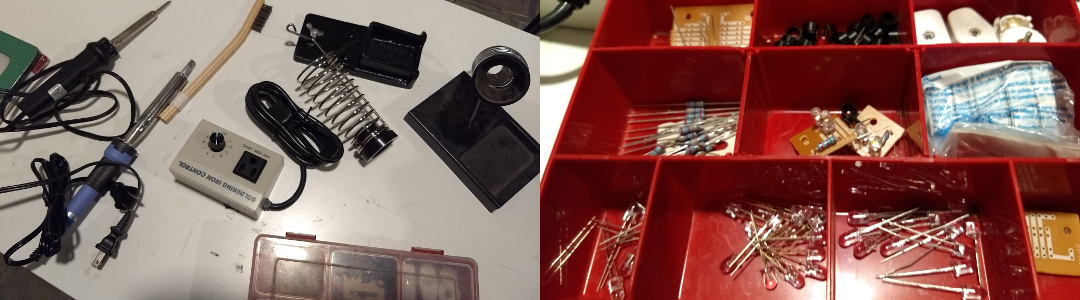

Soldering equipment - a haphazard inventory

Awhile ago, I acquired some soldering irons and assorted accessories. I am particularly excited about what I think is a temperature control for the soldering iron? I’m excited to swap out my current stand for this much sturdier looking stand. I also want to see how well these other irons work compared to the cheap-o one I have.

Too bad that as of 3/19/2020, all of California has been put on a shelter-in-place.

And I left it all at my studio with the intention of grabbing them soon. Oh well! I’ll make do with what I’ve already brought home from my studio.

I LISTENED TO MY FIRST SATELLITE!

It was spontaneous and rushed, but I still got outside right in time to listen to about a minute or so of what sounded like a very expert group of people making contacts with each other as efficiently as possible, very clearly.

More …

“Cut twice, measure once”… right?

Day 1 went a lot slower than I had hoped.

More …